Products

-

MEDIUM-HIGH PERFORMANCE WATER BASED LAMINATING ADHESIVE WD8899A

Used to make high-performance composite film, in a variety of plastic-plastic, aluminum-plastic composite process excellent bonding performance. Good transparency, good wettability, high Primary Adhesive and Peel Strength. Suitable for plastic film composite plastic film, aluminum plating, aluminum foil high-speed composite processing technology.8899A can be used either as One-Part or as a Two Part with special curing agent added.

-

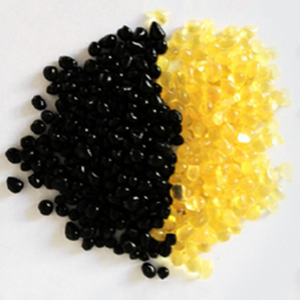

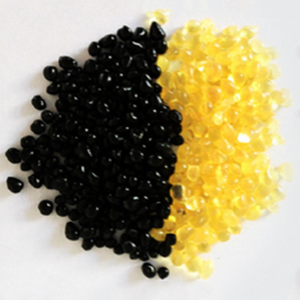

LOW PRESSURE INJECTION LR-ZSB-190

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

LOW PRESSURE INJECTION LR-ZSB-180

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

LOW PRESSURE INJECTION LR-ZSB-170G

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

LOW PRESSURE INJECTION LR-ZSB-170

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

LOW PRESSURE INJECTION LR-ZSB-150-3

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

LOW PRESSURE INJECTION LR-ZSB-150

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

LOW PRESSURE INJECTION LR-ZSB-150-2

Features

·This product has the characteristics of wide temperature resistance, good thermal stability, good electrical insulation and excellent flame retardant, etc. It is mainly used in low pressure injection molding industry.

·The product has a low viscosity in the molten state, so it can ensure to be finished injection under lower pressure, and to protect the precision / sensitive components from damage.

·Solvents free, no toxicity, no environmental pollution.

-

1-300x225.jpg)

HOT MELT ADHESIVE FOR SHOE LASTING LR-QBA

It is a copolyester hot melt adhesive used for shoe lasting and shoe making machine.It is high tensile strength and adhesion strength.It is fast solidification. High efficiency, especially suit assembly line.It can be used under -20 to 160℃, and has wide applicable temperature range.No solvent, no toxicity, no environmental pollution.

-

HOLT MELT ADHESIVE FOR SHOE HEEL LASTING LR-QBA-HBB

It is a copolyamide hot melt adhesive used for Heel lasting and shoe making machine.

·It is high tensile strength and adhesion strength.

·It is fast solidification. High efficiency, especially suit assembly line.

·It can be used under -20 to 100℃, and has wide applicable temperature range.

·No solvent, no toxicity, no environmental pollution.

-

HOLT MELT ADHESIVE FOR SHOE LASTING LR-QBA-3

It is a copolyester hot melt adhesive used for shoe lasting and shoe making machine.

·It is high tensile strength and adhesion strength.

·It is fast solidification. High efficiency, especially suit assembly line.

·It can be used under -20 to 160℃, and has wide applicable temperature range.

·No solvent, no toxicity, no environmental pollution.

-

WD8196 Single Component Laminating Adhesive For Flexible Packaging

Our solvent-free WANDA laminating adhesives deliver a series of solutions for flexible packaging. With close connections to our customers, our researchers and technical engineers are devoted to developing latest production methods and solutions.